- 首 頁HOME

- 關于力威ABOUT US

- 新聞資訊NEWS

- 產品中心PACE DESIGN

- 行業案例INDUSTRY CASE

- 技術服務TECHNICAL SERVICES

- 聯系我們CONTACT US

400 0123 662 全國咨詢熱線

英語

EN

0371-66362555

0371-66362555 18839785775

18839785775

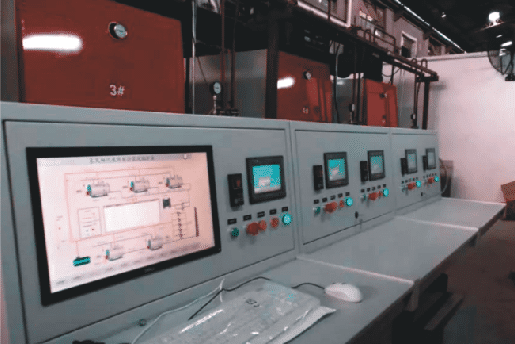

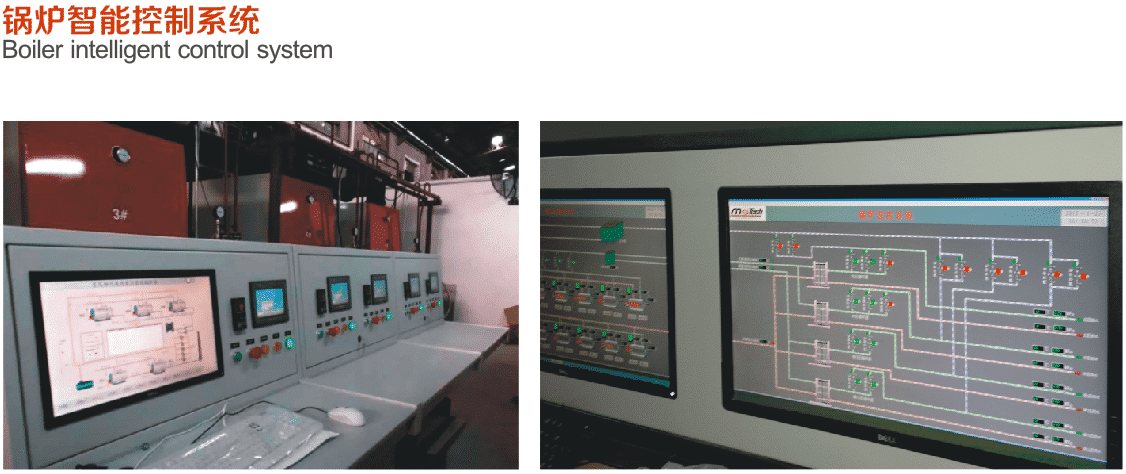

控制系統Control system

燃氣泄漏程序的自動檢測達到安全控制

三元給水自動條件,鍋爐負荷的自動調節,保證長期穩定輸出高品質的蒸汽

溫度、壓力、水位、流量、氧含量的自動檢測、控制和保護

鍋爐啟停時間的預設置

通過上位機可監控鍋爐房內所有鍋爐的運行狀態及單臺鍋爐的詳細運行狀態,實現遠程控制

The automatic detection of gas leak program achieves safety control

Three-way automatic feed water condition, automatic regulation of boiler load, ensure long-term stable output of high quality steam

Automatic detection,control and protection oftemperature, pressure, water level, flow rate and oxygen content.

Preset boiler start/stop time

The operation state of all bollers in the boller room and the detaled operation state of a single boiler can be monitored by the upper computer to realize remote control

操作系統Operatingsystem

全中文觸摸屏為鍋爐人機操作界面

全中文菜單顯示,使鍋爐監控簡單化,調理化,智能化

觸摸屏可實行,動態地顯示鍋爐水位、壓力、溫度、燃燒火力、風機、水泵等運行狀況,鍋爐運行狀態一目了然各控制參數可在觸摸屏上根據需要自由設定

操作程序的多重窗口顯示和豐富的在線幫助功能,提示操作人員如何進行下步操作

The all-Chinese(English) touch screen is the man-machine operation interface of the boier

The al-Chinese(English) menu dispiayThe boller monitoring is simplified, rationalized and intelligent

The touch screen can be implemented to dynamically display the boer water level, pressure. temperature. combustior power, fan, water pump and other operating conditions. so that the boiler operating state is clear at a glance.

Each control parameter can be set freely on the touch screen according to needs

The multi-window display and rich online help function of the operation

記憶系統Memory system

自動記錄當前故障發生的時間和原因

累計記錄總點火次數,風機、水泵和燃燒器運行時間

自動繪制壓力、溫度等參數的曲線

自動記錄熱水/蒸汽用量,為能源管理提供數據基礎

Automatically record the time and cause of the current failure

Total ianition times, fan, water pump and burner running time are recorded

Automatically draw the curve of pressure, temperature and other parameters

Automatic recording of hot water/steam usage to provide a data base for energy management.